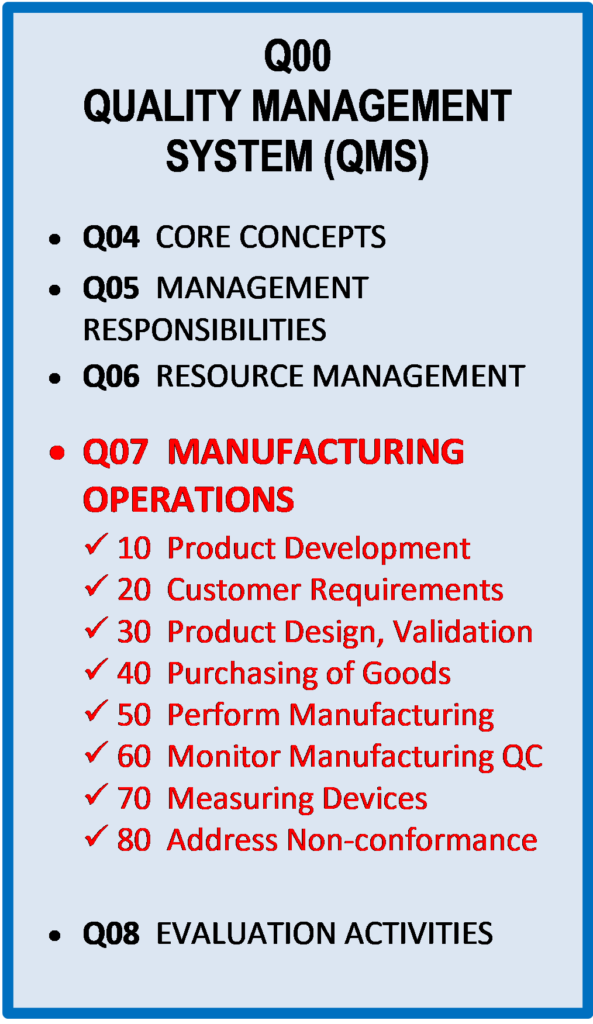

Q07 Manufacturing Operations in Quality Management System

Q07-0000 Manufacturing Operations in Quality Management System

The Manufacturing Operations is the core of most businesses’ quality system:

- Q07-10 Product Realization –

- this is the planning of product objectives, resource requirements.

- Develop a Quality Plan.

- Q07-20 Customer Requirements –

- determine Statutory and regulatory requirements applicable to the product

- Q07-30 Product Design, Validation –

- Plan and control the product design and development.

- Appropriate review, verification, and validation activities for each stage

- Q07-40 Purchasing of Goods –

- Evaluate and select suppliers based on their ability to supply product in accordance with the requirements.

- Establish the criteria for selection, evaluation, and re-evaluation.

- Maintain the results of the evaluations and subsequent follow-up actions.

- Q07-50 Perform & Monitor (QC) Manufacturing – Plan and carry out production and service provision under controlled conditions to include, as applicable:

- develop product characteristics information

- Availability of work instructions

- Ensure suitable equipment and resource

- Validation – Equipment Qualification, Process Validation, Cleaning Validation

- Implementation of product release, delivery, and post-delivery activities

- Q07-70 Measuring Devices –

- control of monitoring & measuring devices

- Determine the monitoring and measurements to be made, and the required equipment, to provide evidence of product conformity.

- Use and control the monitoring and measuring devices to ensure that measurement capability is consistent with monitoring and measurement requirements.

- Calibration program & schedules for devices

- Q07-80 Address Non-conformance

Showing all 4 results