E03-5000 Project Quality System

What is a Project Quality System?

It is a term used to describe the overall framework and processes, and the various elements (procedures, forms and resources) involved in improvements to projects. Improvements include quality of work, compliance, cost and schedule.

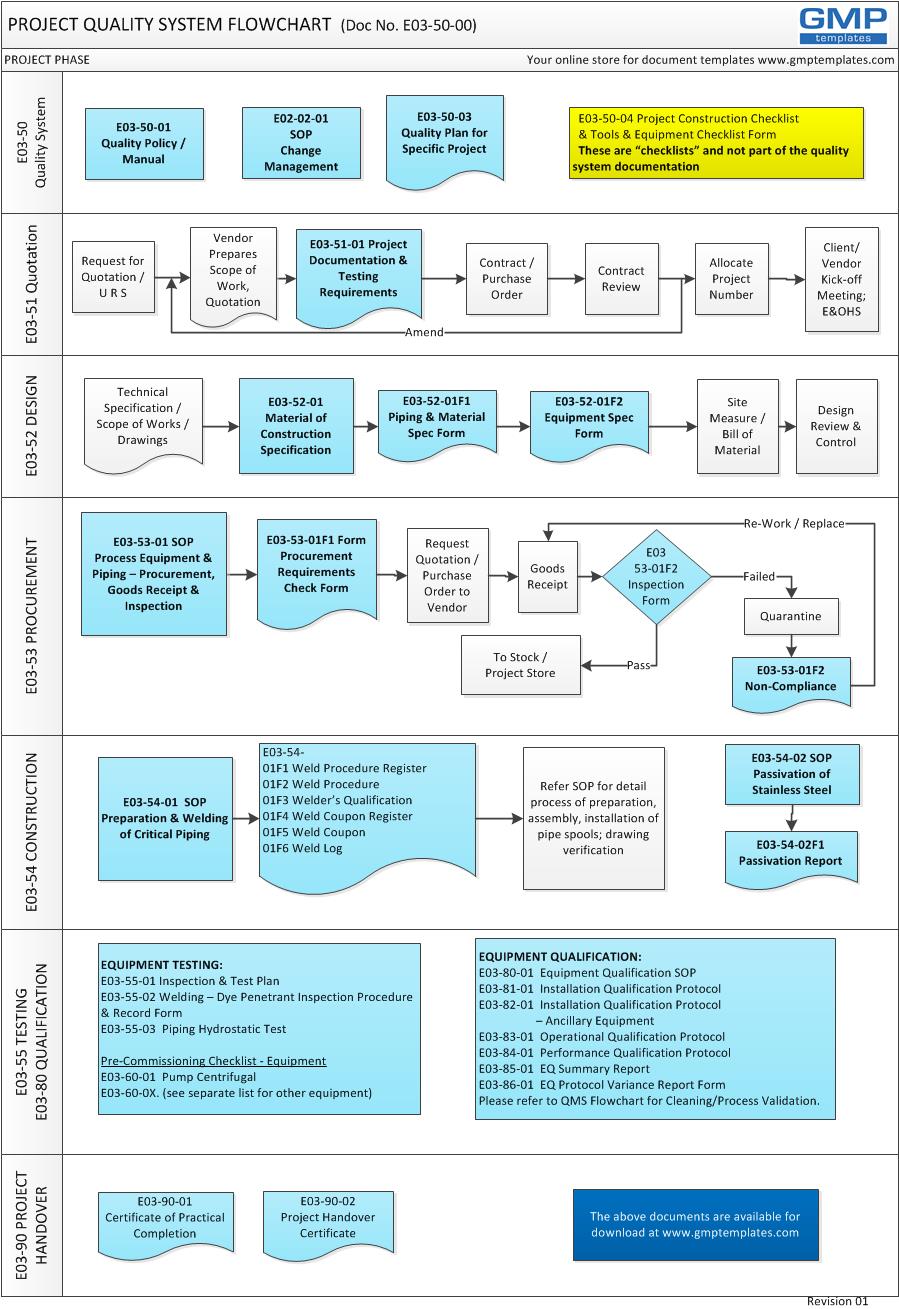

Project Quality System model – the flowchart shows the processes, procedures and forms for the system. – Click Here to open PDF – E03-50-00_Project_Quality_Sys_Flowchart

E03-50-00_Project_Quality_Sys_Flowchart

WHY DO WE NEED A PROJECT QUALITY SYSTEM?

Common weaknesses in executing GMP-Projects are:

- that the Regulatory/GEP/GMP requirements expected by the Client are not well defined and relayed to the Contractor

- Client as well as Contractor does not have a quality system in place – there is no baseline to benchmark

- the processes and expectations are not mapped out – so that every team member understands the requirements, procedures and expected outcomes

- The quality system model will take you through each logical step to ensure deliverables to GMP Projects are met with maximum quality, compliance, cost and timeline benefits.

A QUALITY SYSTEM SHOULD:

- Set project quality standards, targets, deliverables and acceptance criteria ie Quality Policy and Plan

- Define how those quality targets will be measured, documented and tested

- Take the actions needed to measure quality

- Identify quality issues and improvements

- Define the Testing and Qualification processes to report how the required acceptance criteria are met.

WHEN A QUALITY SYSTEM IS PROPERLY IMPLEMENTED:

- it will minimize rejects, rework and project scope variations

- the processes and documentation generated are transferable from design through to equipment qualification – ie avoid repetitive documentation

- the expectations from all stakeholders can be met, and so on.

SCOPE OF A QUALITY SYSTEM:

- The procedures and forms in the system cater for all stakeholders from the Client, Equipment Suppliers to Contractors.

- The procedures are practical “no-frills” approach and written for the “layman” – easy to understand and implement. The system is most suited to medium size project but can be extended for larger projects and multiple disciplines (eg electrics and controls).

- all the processes, procedures and forms are well proven and have been implemented by many Design/Construct Contractors and by Client Project Teams in GMP Facilities.

The processes, procedures and forms are listed in the flowchart below

A Free Whitepaper is available for download – E03-5000 A Simple Quality System Model for GMP Projects (also see listing below)

-

E03-5100 Project Quality System - Core Concepts (7)

-

E03-5200 Project Quality System - Design SOP (1)

-

E03-5300 Project Quality System - Procurement (1)

-

E03-5400 Project Quality System - Construction (2)

-

E03-5500 Project Quality System - Testing & Commissioning (4)

-

E03-8000 Project Quality System - Equipment Qualification (5)

-

E03-9000 Project Quality System - Project Handover (2)