Description

What is this process and document about?

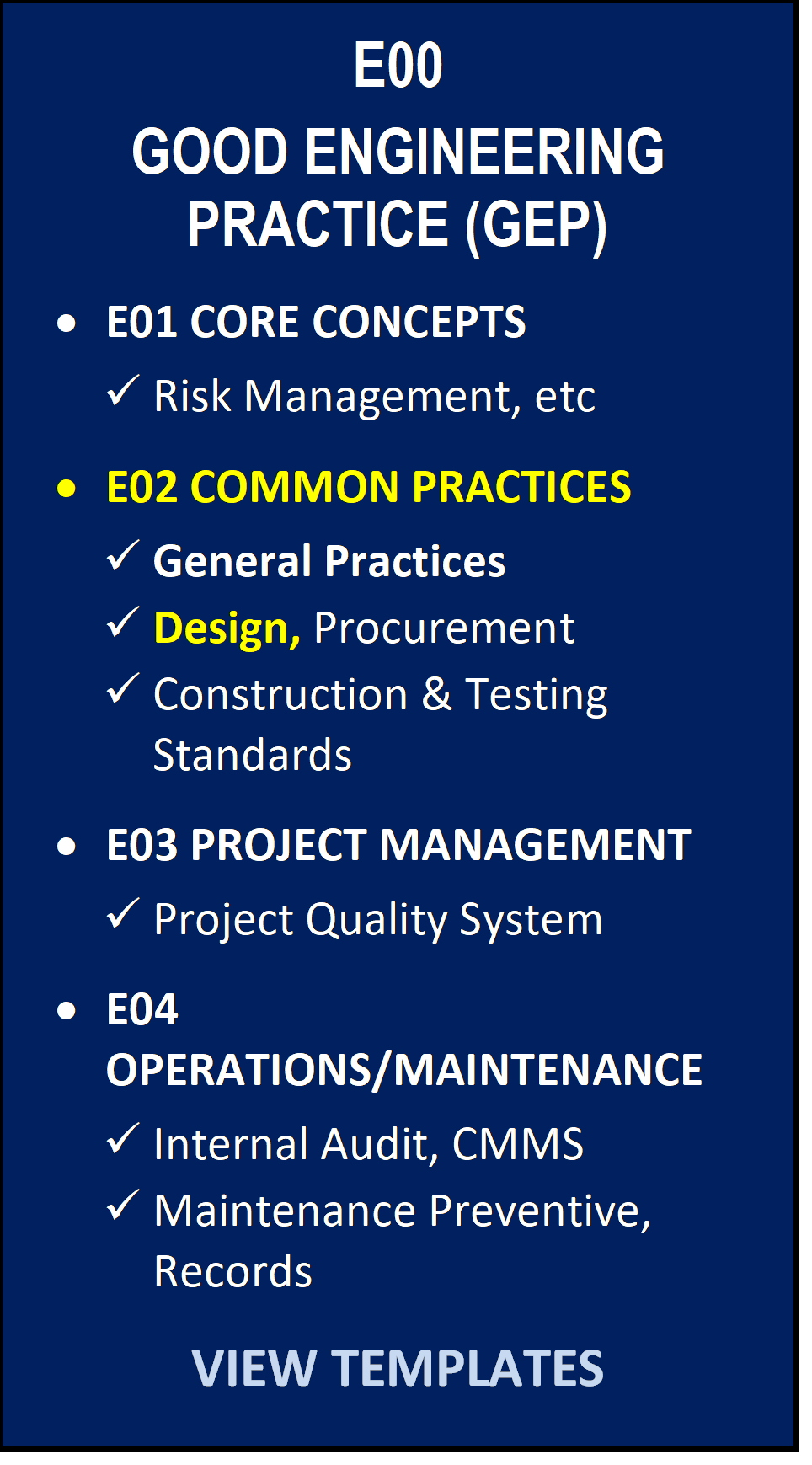

- Control of Equipment is fundamental to Good Engineering Practice (GEP), Good Manufacturing Practice (GMP) and compliance to ensure the correct and well-maintained equipment is fit for “intended use” to produce quality products.

- This Standard Operating Procedure (SOP) provides guidance to the development, management and control of engineering and laboratory equipment and utilities throughout its life-cycle.

- A “Good Engineering Practice” (GEP) and Quality Management System (QMS) flowcharts provide the ‘big picture’ of the relations of this and associated process and documentation.

This document has 2 parts:

- Part 1 (5 pages) – this introduction describes the rationale of why this procedure or standard is required, cross reference to relevant regulatory clauses or industry best practices.

- Part 2– the standard operating procedure (SOP) template (12 pages) + 5 Forms

Attachments & Forms included:

There are 4 “must-have” form templates that will assist you to CONTROL & MANAGE your equipment and facility:

- Equipment Specification Datasheet – the critical and essential information regarding the equipment is kept in the datasheet. This is an interactive form guiding you through the life cycle of the equipment – from the initial performance requirements, design, construction, qualification through to maintenance and retirement.

- Master Equipment/Instrument List – this GMP document is a popular request from regulatory auditors. The two spreadsheets have columns for the essential information that an auditor will request.

- Instrument Calibration Control Form – similar to an equipment datasheet, this form relates to an instrument.

- Weighing Device Calibration Form – similar to an equipment datasheet, this form relates to a weighing device.

Associated Industry/regulatory guidance and requirements:

- FDA (US) Q7A Good Manufacturing Practice Guidance for Active Pharmaceutical Ingredients, August 2001), Sections 4.2, 5.1.

- PIC/S PE 009-8 2009 Guide GMP Medicinal Products – Part 1: 3.42, 3.44

- ASTM E2500-7 Standard Guide for Specification, Design, and Verification of Pharmaceutical and Biopharmaceutical Manufacturing System and Equipment; Clause 6.6.3.3

- ISPE Good Practice Guide: Good Engineering Practice

Included Sections:

DOCUMENT TEMPLATE – Purpose, Scope, Training, , References and Associated Documents, Definitions/Acronyms, Responsibility, Procedures, Attachments.

Who needs this document:

- Any department who uses equipment, instruments & utilities in R&D, manufacturing, testing, laboratories, logistics.

- Engineering department

- Quality Control

- Manufacturing

- Engineering & Instruments Vendors and Contractors

Related Documents:

E00-01-01 Policy Statement on Good Engineering Practice

E02-02-01 Change Control (Engineering)

E02-21-10 Control of Engineering Drawings

E02-21-02 Drawing sheet Template – P&ID Symbols Sheet 1 of 2

E02-21-03 Drawing sheet Template – P&ID Symbols Sheet 2 of 2

E02-21-04 Drawing sheet Template – Isometric A3 Size

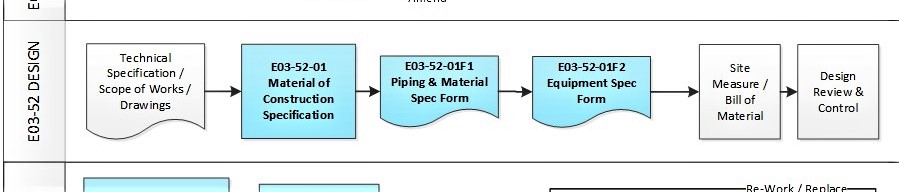

In addition, some of the typical DESIGN processes and documents for a small GMP design and construct project is shown below:

E03-50-00 Project Quality Sys Flowchart – Design

To view the entire E03-5000 Project Quality System Flowchart

Keywords:

Process equipment control, instrument, calibration GEP tagging identification equipment specification performance datasheet Master Equipment List Weighing device