Description

What is this procedure and document about?

- Welding is a fabrication process that joins materials, usually metals or thermoplastics, by causing coalescence. This is often done by melting the work-pieces to form a pool of molten material (the weld pool) that cools to become a strong joint, …… to produce the weld. Source: Wikipedia

- The weld can have an indirect effect on the quality of pharmaceutical products processed in the equipment or transferred in the piping. The preparation and welding process:

- May introduce mild steel contaminants onto stainless steel surfaces

- The internal weld bead should not be concave or too convex – this will provide an area to harbor contaminants (eg particles or bacteria)

- Should not introduce free ferrite which is one of the possible causes to “Stainless Steel Rouging”. Rouging of stainless steel is the result of the formation of iron oxide, hydroxide or carbonate either from external sources or from destruction of the passive layer. “The mechanism that causes rouging does not appear to be fully understood, but is connected to destabilization of the passive layer. Measures that improve corrosion resistance can help prevent rouging.” – quote British Stainless Steel Association

- The objective of this procedure and associated 6 forms is to provide a consistent method to the preparation and welding process:

- To ensure consistency in the base metal and the resulting weld quality

- To ensure minimal introduction of contaminants (eg mild steel particulates)

- To provide traceability of the process by good documentation. The attached six forms are part of the overall documentation.

- This procedure has been well-proven and used in many real-life GMP Projects. It takes you through a practical step by step of preparing material and documents, through to cleaning, inspection and acceptance criteria of welds.

- This document is one of the construction processes in a “Project Quality System”. A Project may include all or in part the design, fabrication (may include welding), installation, testing and passivation of process equipment and piping.

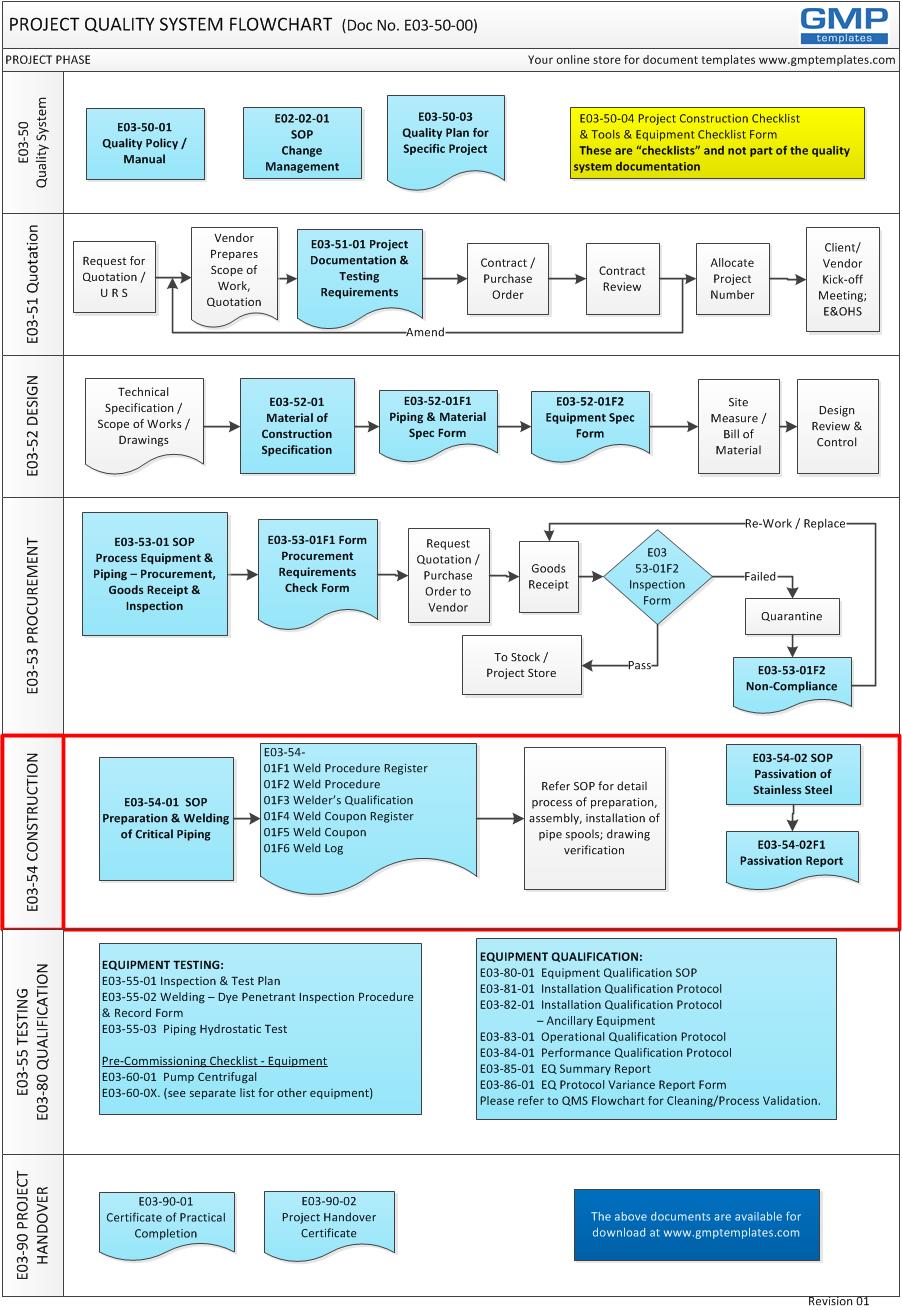

- A process map of a typical Project Quality System is shown below. The flowchart guides you through each project phase from “Request for Quotation” to “Equipment Qualification”.

Forms included:

- E03-54-01F 1 Welding Procedure Register

- E03-54-01F 2 Welding Procedure

- E03-54-01F 3 Welder Qualification Test

- E03-54-01F 4 Weld Coupon Register

- E03-54-01F 5 Weld Coupon

- E03-54-01F 6 Welding Log Sheet

- E03-54-01 Preparation and Welding of Piping – Flowchart in Microsoft Visio format

Reference – Industry/regulatory guidance and requirements:

- ISPE Good Practice Guide: Good Engineering Practice

- ASTM E2500-7 Standard Guide for Specification, Design, and Verification of Pharmaceutical and Biopharmaceutical Manufacturing System and Equipment

Included Sections:

- Part One – an introduction to the procedure template (3 pages)

- Part Two – the template has following sections (6 pages) – Purpose, Scope, References and Associated Documents, Responsibility, Procedures, Attachments (6 Forms). CLICK HERE to view table of contents.

Keywords:

Project Quality System, Welding of critical piping

Who needs this document?

- Vendors – equipment fabricators and manufacturers; mechanical piping contractors

- Any department who uses equipment & utilities in R&D, manufacturing, testing, laboratories.

- Projects, Validation, Engineering department

- Quality Control

- Manufacturing

Related Documents:

- E03-50-00 Project Quality System Flowchart

- E03-50-01 Project Quality System Policy

- E03-50-02 Project Change Control

- E03-50-03 Project & Quality Plan (Concise)

- E03-50-04 Project Construction Checklist

- E03-51-01 Project Documentation & Testing Requirements

- E03-52-01 Material of Construction Specification

- E03-53-01 Project Procurement & Inspection Procedure

- E03-54-01 Preparation & Welding of Critical Piping – this document

- E03-54-02 Passivation of Stainless Steel & Record Form

EQUIPMENT TESTING & QUALIFICATION:

- E03-55-01 Inspection & Test Plan (Form)

- E03-55-02 Welding – Dye Penetrant Inspection Procedure & Record Form (E03-55-02F1)

- E03-55-03 Piping Hydrostatic Test Procedure & Form

- E03-55-04 SOP EQUIPMENT QUALIFICATION:

- E02-56-01 Project Handover – O&M Manual