Description

What is Passivation?

Passivation is the process of making a material “passive”. With reference to corrosion, passivation is the spontaneous formation of a hard non-reactive surface film that inhibits further corrosion. This layer is usually an oxide or nitride that is a few molecules thick. Passive surfaces are resistant to reactions, including corrosion reactions.

The original passive oxide layer of the raw stainless steel material can be damaged:

- through mechanical means during fabrication process (bending/rolling of the sheet metal)

- Welding creates a heat affected zone in which the alloy structure is altered

- Chemical damage to the passive layer can be caused by exposure to chlorides. Bleach, salt, and oceanic environments are especially harsh on stainless steel.

The passivation process will restore the passive layer, remove metal particles, dirt, and welding-generated compounds (e.g. oxides). Passivation is the last process of the equipment and piping before exposure to the product during testing and commissioning.

What is this good practice process and document about?

- This standard operating procedure (SOP) provides a method to passivate stainless steel surfaces of equipment and piping to enhance corrosion resistance. It is not about the chemistry of passivation – we are leaving this to the Subject Matter Expert ie chemicals suppliers. This SOP is about the practical approach to setting up the system and relevant documentation, provide useful tips (eg bleeding out air pockets) and testing.

- This document template is more than an SOP – it includes the rationale of why, what, who and how to do it

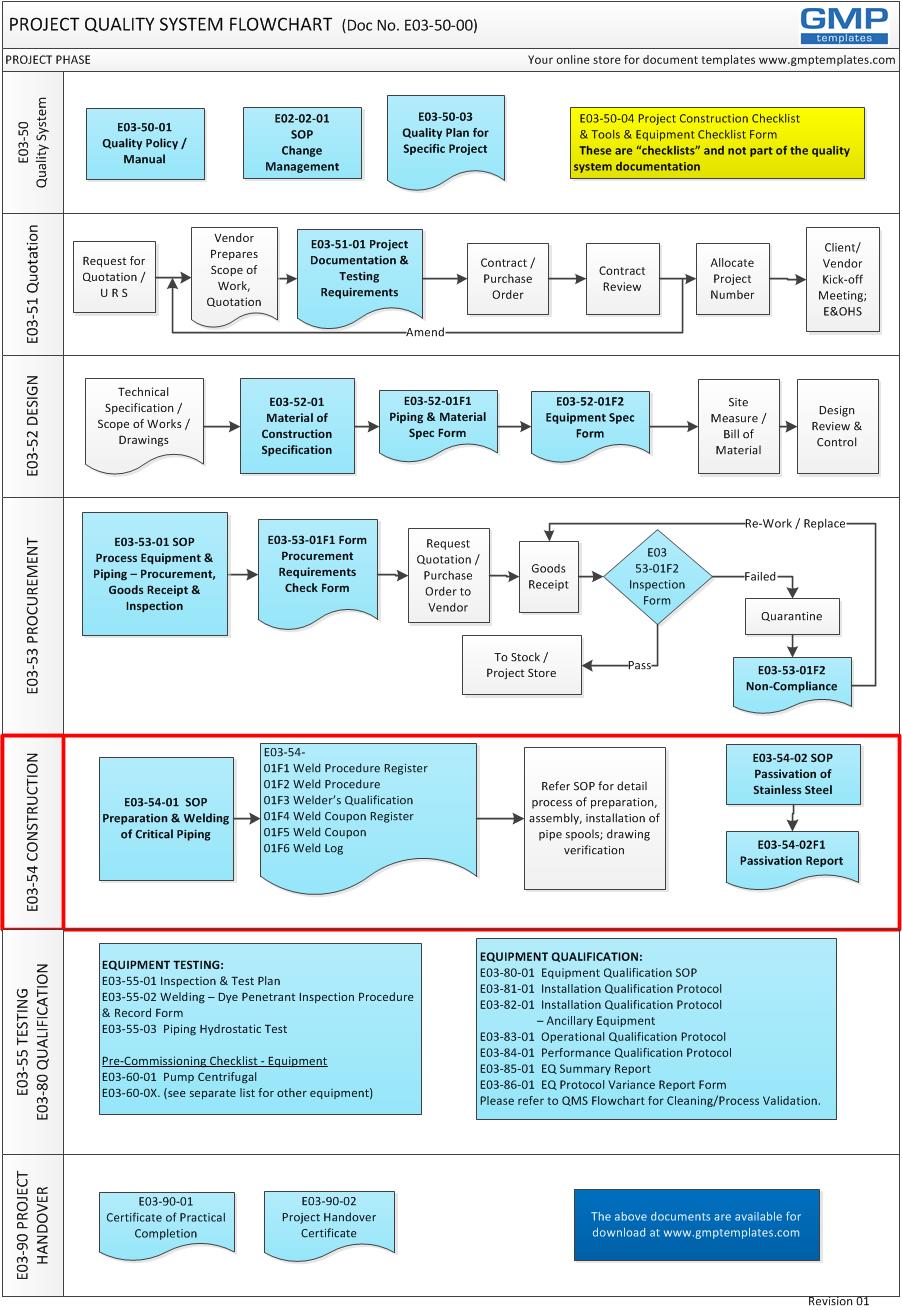

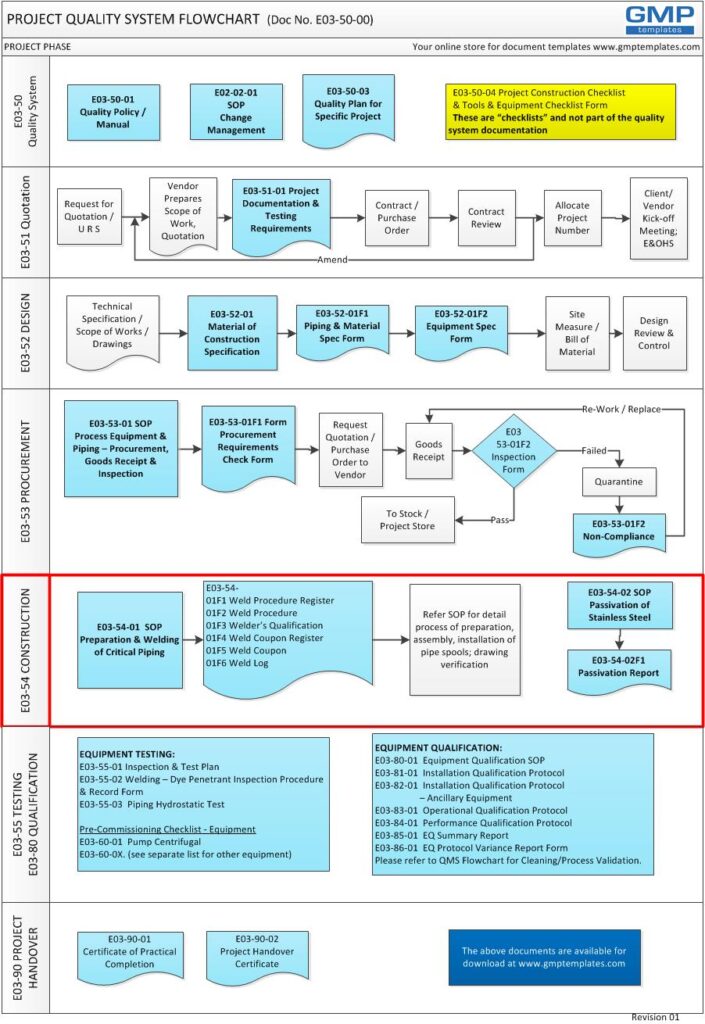

- This procedure is part of the Construction process in a Project Quality System (see flowchart below)

- There are two Parts to this document

- Part One – An introduction to the background of the topic; why this process and document are required, relationship with other documents and processes (3 pages)

- Part Two – The document template (Standard Operating Procedure SOP) 4 pages and Passivation Form/Report (3 pages)

E03-5000 GMP Project Quality System Construction Procedure

Associated Industry/regulatory guidance and requirements:

- ASTM A 967, “Standard Specification for Chemical Passivation Treatments for Stainless Steel Parts”

- ASTM A 380, Standard Practice for Cleaning, Descaling, and Passivation of Stainless Steel Parts, Equipment, and Systems. A 380 is now outdated and A 967 should be referred to

Included Sections:

Purpose, Scope, References and Associated Documents, Definitions /Acronyms, Responsibility, Procedures, Attachment.

Keywords:

Equipment Piping Passivation Cleaning Descaling Stainless steel surface ferrite Corrosion resistance

Who needs this document:

- Vendors – equipment fabricators and manufacturers;

- mechanical piping contractors

- Any department who uses equipment & utilities in R&D, manufacturing, testing, laboratories.

- Projects, Validation, Engineering department

- Quality Control

- Manufacturing

Related Documents:

- E03-50-00 Project Quality System Flowchart

- E03-50-01 Project Quality System Policy

- E03-50-02 Project Change Control

- E03-50-03 Project & Quality Plan (Concise)

- E03-50-04 Project Construction Checklist

- E03-51-01 Project Documentation & Testing Requirements

- E03-52-01 Material of Construction Specification

- E03-53-01 Project Procurement & Inspection Procedure

- E03-54-01 Preparation & Welding of Critical Piping

- E03-54-02 Passivation of Stainless Steel & Record Form – this document

EQUIPMENT TESTING & QUALIFICATION:

- E03-55-01 Inspection & Test Plan (Form)

- E03-55-02 Welding – Dye Penetrant Inspection Procedure & Record Form (E03-55-02F1)

- E03-55-03 Piping Hydrostatic Test Procedure & Form

- E03-60-03 Pre-Commissioning Checklist – Pump (Centrifugal)

- E03-60-XX – see separate list for other major equipment

- E03-80 SOP EQUIPMENT QUALIFICATION

- E02-56-01 Project Handover – O&M Manual