Description

What is Dye Penetrant Inspection?

Dye penetrant inspection (DPI), also called liquid penetrant inspection (LPI) or penetrant testing (PT), is a widely applied and low-cost inspection method used to locate surface-breaking defects in all non-porous materials (metals, plastics, or ceramics).

The penetrant may be applied to all non-ferrous materials and ferrous materials, but for inspection of ferrous components magnetic-particle inspection is also preferred for its subsurface detection capability. LPI is used to detect casting, forging and welding surface defects such as cracks, suface porosities, and leaks in new products, and fatigue cracks on in-service components. Source: Wikipedia

What is this document about?

- It defines the procedure to be used for identifying defects in stainless steel parts, equipment and pipework.

- DPI is to be performed after mechanical works have been done (including welding and polishing). This procedure applies to the Dye Penetrant Inspection stainless steel parts, equipment and nominated pipework.

- The areas to be inspected will be derived using a Risk-based approach.

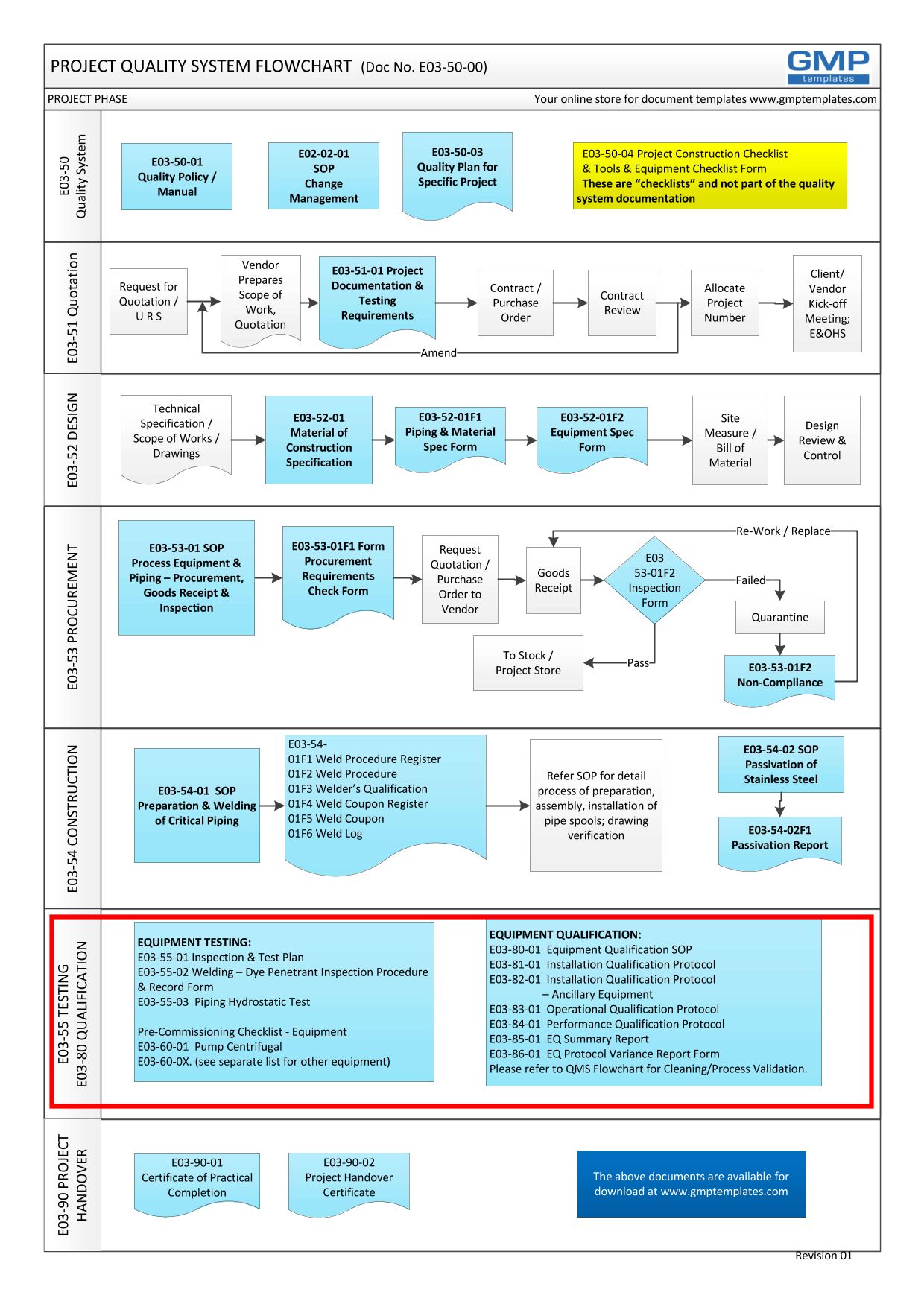

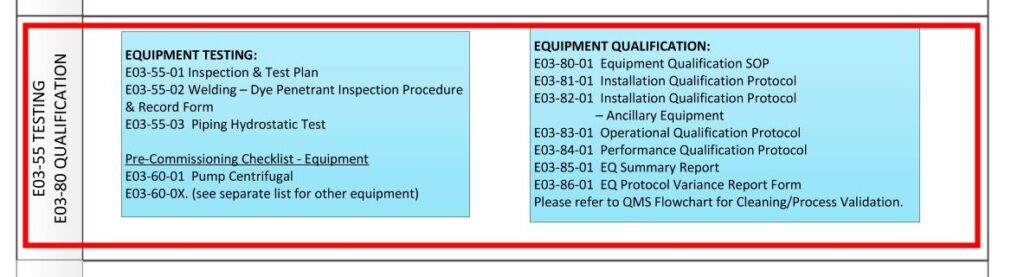

- The report will form one of the acceptance criteria for the mechanical work or installation qualification. This process is one of the components of a Project Quality System (see flowchart below)

- The document consists of a procedure and a report form. The procedure provides a practical hands-on guide to the preparation and testing processes.

E03-5000 Project Quality System Flowchart – IQ-OQ

Keywords:

Dye Penetrant Inspection Welding cracks

Who needs this document:

- Vendors – equipment fabricators and manufacturers;

- mechanical piping contractors

- Any department who uses equipment & utilities in R&D, manufacturing, testing, laboratories.

- Projects, Validation, Engineering department

- Quality Control

- Manufacturing

Related Documents:

E03-50-00 Project Quality System Flowchart

E03-50-01 Project Quality System Policy

E03-50-02 Project Change Control

E03-50-03 Project & Quality Plan (Concise)

E03-50-04 Project Construction Checklist

E03-51-01 Project Documentation & Testing Requirements

E03-52-01 Material of Construction Specification

E03-53-01 Project Procurement & Inspection Procedure

E03-54-01 Preparation & Welding of Critical Piping

E03-54-02 Passivation of Stainless Steel & Record Form

EQUIPMENT TESTING & QUALIFICATION:

E03-55-01 Inspection & Test Plan (Form)

E03-55-02 Welding – Dye Penetrant Inspection Procedure & Record Form – this document

E03-55-03 Piping Hydrostatic Test Procedure & Form

E03-60-03 Pre-Commissioning Checklist – Pump (Centrifugal)

E03-60-XX – see separate list for other major equipment

E03-80 SOP Equipment Qualification

E02-56-01 Project Handover – O&M Manual