Description

What is Equipment Qualification?

The design, construction and delivery of manufacturing systems and equipment into a facility requires a systematic approach in order to meet the user requirements and that of the relevant authorities like cGMP, local governing codes, law and regulations.

Equipment Qualification is the action of proving and documenting that the equipment and ancillary systems are properly installed, work correctly, and actually lead to the expected results. This is to ensure that all critical aspects or acceptance criteria for its intended use are met. Qualification is part of the validation process which is a regulatory compliance requirement.

The three components of Equipment Qualification are:

- Installation Qualification (IQ) – documented verification that the equipment or systems, as installed or modified, comply with the approved design, the manufacturer’s recommendations and/or user requirements. Source: PIC/S

- Operational Qualification (OQ) – documented verification that the equipment or systems, as installed or modified, perform as intended throughout the anticipated operating ranges. Source: PIC/S

- Performance Qualification (PQ) – documented verification that the equipment and ancillary systems, as connected together, can perform effectively and reproducibly based on the approved process method and specifications. Source: PIC/S

What is this document about?

- The purpose of this protocol template is to outline the tests required for Performance Qualification of a system.

- This protocol plays a role in two areas:

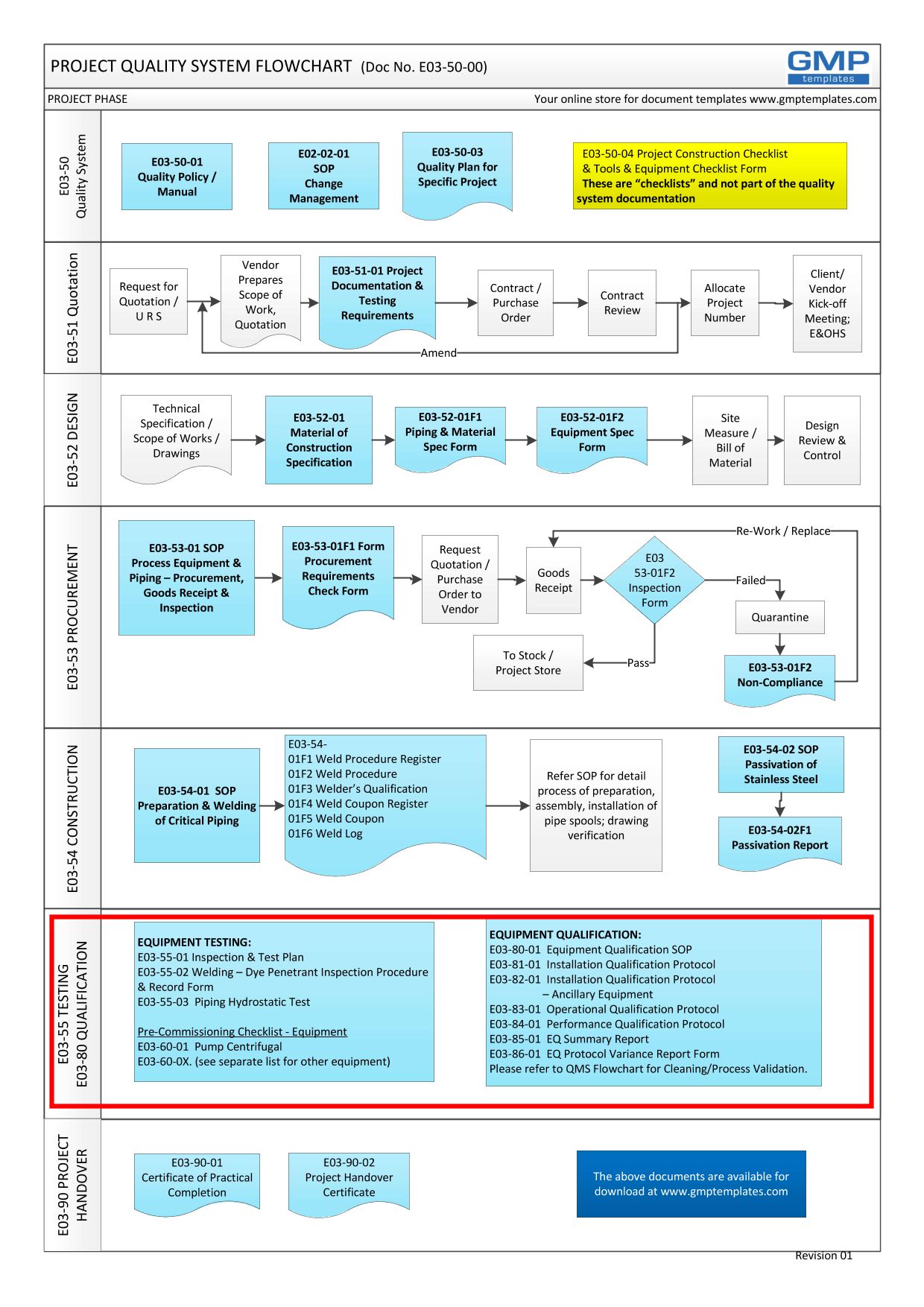

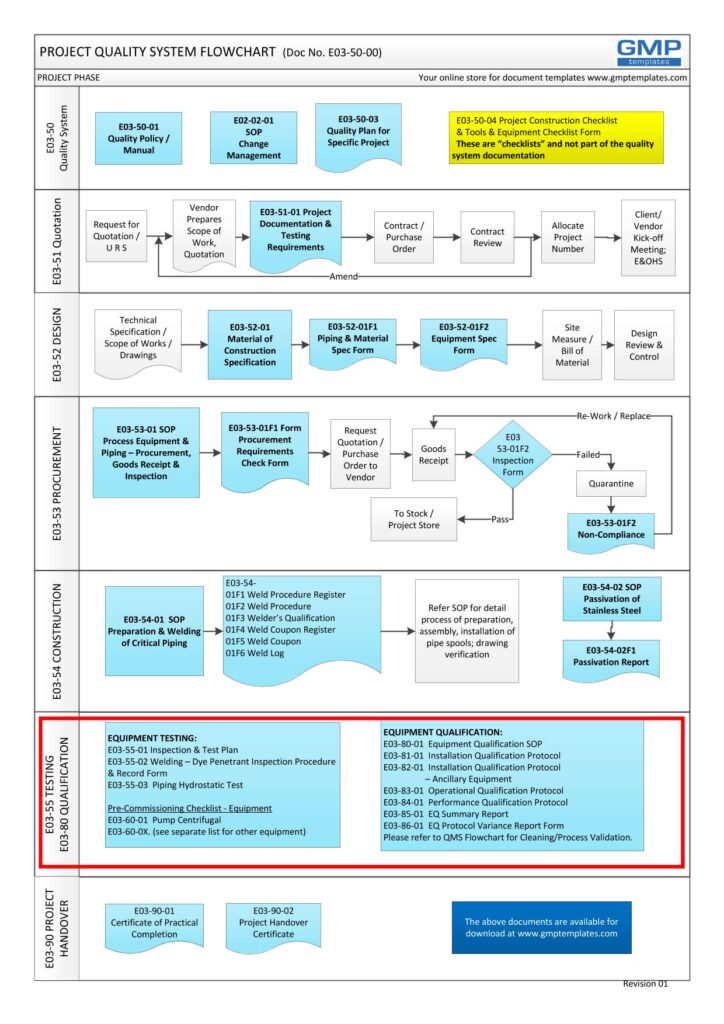

- Good Engineering Practice – it is part of the Testing process in a Project Quality System (see flowchart below)

- Quality Management System for a GMP facility – this protocol is a component of Facility & Equipment under Resource Requirements – View QMS Flowchart q00-00-01_qms_flowchart

- This well proven document has been used in numerous GMP facilities

- The document has two Parts:

- Part One – an introduction to the template – 4 pages

- Part Two – a 10-page protocol template + attachments

Attachments & Forms include:

- E03-80-01F1 Qualification Summary Report (4 pages) – this is a guide as to what should be included in a report

- E03-80-01F2 Protocol Variance Report Form (2 pages) – it guides you through a typical deviation investigation and CAPA process.

E03-50-00 Project Quality System Flowchart – Testing, commissioning and Qualification (Validation)

Click the hyperlink here to open an Adobe PDF version E03-50-00_Project_Quality_Sys_Flowchart

Associated Industry/regulatory guidance and requirements:

- ISPE Baseline Guide – Commissioning and Qualification

- FDA CFR Part 211 Subpart C (Building and Facilities) and Subpart D (Equipment)

- PIC/S Guide to GMP for Medicinal Products Part I (Clause 1.4/xi) and II (12.3 Qualification)

- ASTM E2500 Specification, Design, and Verification of Pharmaceutical and Biopharmaceutical Manufacturing System and Equipment

Included Sections:

Purpose, Scope, Background, Equipment/System Description, References Documents, Critical Aspects & Acceptance Criteria, Pre-Qualification Requirements, Tests and Checks, Variance Log, Appendices.

Keywords:

Equipment Qualification EQ Installation Qualification (IQ) Operational Qualification (OQ) Performance Qualification (PQ)

Who needs this document?

- Vendors – equipment fabricators and manufacturers; mechanical piping contractors

- Any department who uses equipment & utilities in R&D, manufacturing, testing, laboratories.

- Projects, Validation, Engineering department

- Quality Control

- Manufacturing

Related Documents:

E03-50-00 Project Quality System Flowchart

E03-50-01 Project Quality System Policy

E03-50-02 Project Change Control

E03-50-03 Project & Quality Plan (Concise)

E03-50-04 Project Construction Checklist

E03-51-01 Project Documentation & Testing Requirements

E03-52-01 Material of Construction Specification

E03-53-01 Project Procurement & Inspection Procedure

E03-54-01 Preparation & Welding of Critical Piping

E03-54-02 Passivation of Stainless Steel & Record Form

EQUIPMENT TESTING & QUALIFICATION:

E03-55-01 Inspection & Test Plan (Form)

E03-55-02 Welding – Dye Penetrant Inspection Procedure & Record Form

E03-55-03 Piping Hydrostatic Test Procedure & Form

E03-60-XX Pre-Commissioning Checklist – various equipment

E03-60-01 Pre-Commissioning Checklist – Pump (Centrifugal)

E03-80-01 Equipment Qualification SOP

E03-80-01F1 Qualification Summary Report

E03-80-01F2 Protocol Variance Report Form

E03-81-01 IQ Protocol Template

E03-82-01 IQ Protocol Template For Ancillary Equipment

E03-83-01 OQ Protocol Template

E03-84-01 PQ Protocol Template (this document)

E02-90-01 Project Handover – O&M Manual